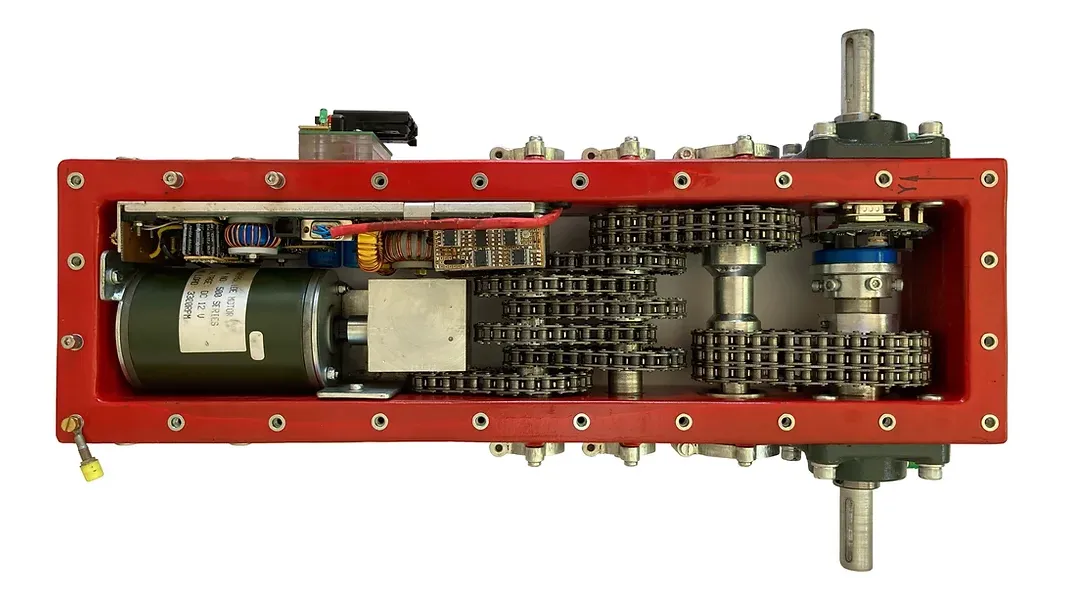

Forearm Actuator

Our quest to design and develop an affordable medium size industrial robotic arm resulted in the following baseline requirements:

- Our robotic arm must be able to carry a payload of about 100kg.

- Our robotic arm must have a reach of about 2m.

- Our robotic arm must have a tool tip positional accuracy of 0.5mm.

- Our robotic arm must be able to work in harsh environments. This environment stemmed from our vision to supply low cost Cobots for widespread industrial use

A tall order, as similar industrial robots commonly achieve positional end effector accuracy of about 1mm. Achieving 0.5mm proved to be very challenging, but also very rewarding. Rewarding in that a number of innovative technologies developed out of the challenge: innovative technologies with great market potential such as our MFEA encoder.

To save volume and weight, our first functional robotic arm, ADM1 was powered by a VW wiper motors in conjunction with an inexpensive tension based chain and sprocket drivetrain. Such a drivetrain is different from those found in typical industrial robots and it turned out to be greatly advantageous.